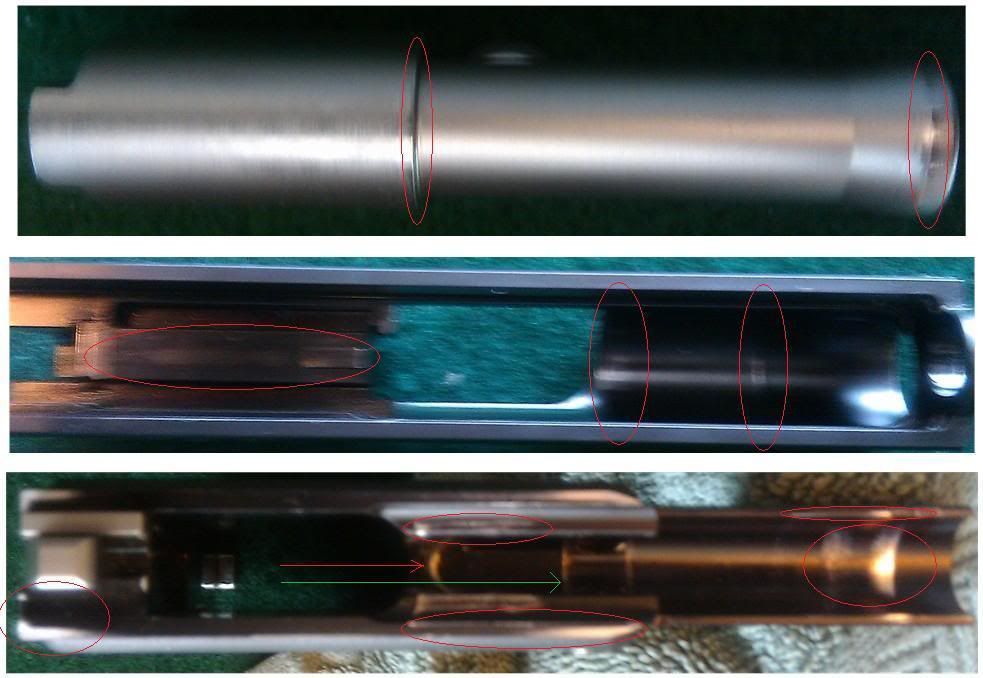

Top: Barrel wear, insignificant burnishing of the metal

Middle: Slide wear, minor finish wear

Bottom: frame wear, finish worn through, slight disruption of the bottom edge of the barrel stop web (red arrow).

The barrel toggle pin shows no markings and I omitted that photo.

Both barrel and slide are in nearly new condition and I will skip any comment of wear in these areas as it is a superfluous area of discussion at this round count.

The frame shows some signs of wear than have not advanced noticeably from rounds 200-340.

Comments on frame wear:

The barrels rearward movement is arrested by a web (red arrow) just in front of the magazine well. A milled inside radius on the forward edge of this web catches a machined outside radius on the very bottom of the barrel toggle, halting the barrel's movement. The lower edge of this web shows the most significant wear, caused from the sharp edge of the radiused lug of the barrel. At this round count a loupe and a close inspection shows some disruption of the aluminum but nothing of concern. It is important to note that this web only absorbs the inertia of the barrel, the inertia of the slide and recoil spring is arrested by a spring seat (green arrow) about 3/4" forward of the web. This spring seat is much more substantial than the web which stops the barrel, the spring seat being almost a complete circle except for the relief at the top where the barrel toggle reciprocates. The wear at the recoil spring seat is through the finish at the outer circumference, but is inconsequential.

Wear at the frame rails is through the finish and has polished the metal under the black anodizing at the very rear of the slide and also at the front of the dust cover. Edges are still square and sharp, and no gouges or flakes are are evident.

The large area on the dust cover (both inside and on the top edges) where the finish is worn is at the location where the front of the slide and spring cup reach as the rear of the slide encounters the angle on the hammer. At this point the rear of the slide is pressed up by the tension of the hammer spring as the hammer is cocked, rocking the front of the slide slightly downward. This wear on the dust cover finish is cosmetic, no ridge or loss of metal is visible with a loupe and straight edge.

The assembly procedure may lead you to believe that the recoil spring seats on fore part of the barrel toggle lug, however this lug is flush (or nearly so) with the spring seat of the frame when the pistol is assembled. The barrel is held in place by the toggle pin camming the barrel up and locking it into the ejection port.

Overall the wear is nearly all cosmetic and of little concern at this early round count, with the only area of any note being the web that arrests the rearward barrel travel. After the barrel and web wear in together I expect peaning in this area to be self limiting. However I will monitor it and let you know.

Although "carry a lot, shoot little" has been chanted as the mantra of these little pistols, to be honest, as of yet there is no observable evidence that this pistol can't take quite a bit of shooting. Admittedly I did not magnaflux the frame, and a loupe and straight edge can only do so much, but with years of shooting and repairs under my belt, I don't see anything that indicates the R9 isn't capable of many thousands of rounds.